1955-57 Fits Chevy 2 Inch Dropped Spindle/Disc Brake Conversion Kit

1955-57 Chevy 2 Inch Dropped Spindle/Disc Brake Conversion Kit. (1) Pair of 1955-57 Chevy 2 Drop Spindles. (1) Pair of 1955-57 Metric Caliper Brackets. (1) Bolt Kit for 1955-57 Drop Spindle to Metric Caliper. (1) GM Metric LH Brake Caliper, 7/16-20 Inlet.

(1) GM Metric RH Brake Caliper, 7/16-20 Inlet. (1) Set of Speedway Soft Street Brake Pads, GM Metric 1978-Up D154. (2) Speedway Replacement Inner Seals.

(2) Inner Wheel Bearing Cones. (2) Outer Wheel Bearing Cones. (1) Spindle Nut Kit for Speedway GM Spindles.

(1) Front Disc Brake Hardware Kit. (1) GM/Corvette Cast Iron Master Cylinder, 1 Inch Bore. (1) GM Disc/Drum Proportioning Valve for 3/8-24 Outlets. Learn more about the products chosen and why we recommend them for your Tri-5 Chevy, here. 1955-57 Chevy 2 Drop Spindles, Aftermarket Disc Brake Kit.

1955-57 Chevy 2 dropped spindles for use with aftermarket disc brake conversion kits. Cannot be used with stock drums or brake conversion for stock type spindle. Maintains factory steering and suspension geometry. Track width is increased over stock O/E front end width by 3/4" overall or 3/8" per side. Ideal for use in conjunction with the following Wilwood brake kit for Heidts Tri-5 drop spindle application. 4-piston 12.19 rotor kit #. These metric caliper brackets have a zinc finish. Steel design is engineered for quality as well as durability. Bolt Kit for 1955-57 Drop Spindle to Metric Caliper.

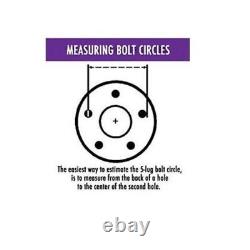

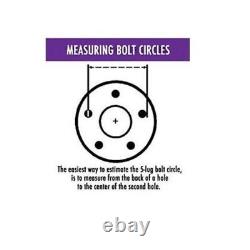

Use these bolt kits to mount your drop spindle conversion to metric calipers. Designed for use with 1955-57 Chevy. On 1979-81 GM Midsize: Malibu, Monte Carlo, Cutlass, Regal, etc. 5 x 4-3/4 bolt pattern. GM Metric LH/RH Brake Calipers, 7/16-20 Inlet.

Stock replacement single piston Metric calipers. Standard equipment on 1978-88 GMmid-size cars Cutlass, Grand Prix, Regals, Monte Carlo, etc. Feature a 2.375 single piston. Can be usedwith brake hoses from Pre-1978 GM intermediate cars. Speedway Soft Street Brake Pads, GM Metric 1978-Up D154. Speedway soft brake pad for GM Metric 1978-Up Calipers. One set outfits two calipers. Only use full metallic pads on coated rotors. Learn how to properly Bed-In your brake pads by reading our tech article. 2.00" x 2.56" x.

Spindle Nut Kit for Speedway GM Spindles. Includes a pair of castle nuts, washers and cotter pins. Castle Nut: 3/4-20 (not SAE, which is 16 TPI). Height up to the bottom of the castellated notch: 0.276. Wrench size for nut: 1.00.

Certain brake kits may require removal of some of the nut material to allow for installation of the cotter pin. GM/Corvette Cast Iron Master Cylinder, 1 Inch Bore. High-tech Corvette-stylemaster cylinders designed using OE specifications and 100% tested. The wide body and low profile gives this master cylinder the clearance you need when installing in tight areas and yet it maintains a large volume of fluid necessary for 2 and 4 wheel disc brake applications.

Has ports on both sides of the master cylinder. Works with power or manual brake systems.

Has a piston adaptor that will allow for power or manual applications. Learn more about selecting the proper master cylinder for your vehicle by reading our tech article. GM Disc/Drum Proportioning Valve for 3/8-24 Outlets. These proportioning valves are similar to what GM used on many cars in the 70s. Non-adjustable and may require an adjustable valve in the rear brakes (if needed).

Block incorporates metering (for front brakes) and proportioning (for rear brakes) into one unit. For use withfront disc, rear drumbrake systems.

Includes hard lines to connect to a master cylinder with 3/8-24 outlets. Bottom Front Port: 3/8-24 IFF threads - goes to one front brake.

Top Front Port: 3/8-24 IFF threads - goes to one front brake. Middle Top Port: 1/2-20 IFF threads - comes from master cylinder. Rear Top Port: 7/16-24 IFF threads - comes from the master cylinder.

Rear Most Port: 9/16-18 IFF threads - goes to rear brakes. Proper Break-In Procedure for Steel or Cast Iron Rotors.

New steel/iron rotors should be bedded in before being used in racing conditions. Proper bedding will prepare the rotor surface, prolong the rotor's life, and make it more resistant to thermal checking or cracking under severe braking conditions.

The following procedures should be performed when bedding in both steel and cast iron rotors. It is best to bed in a new rotor using a used set of pads, preferably ones which will not create heat rapidly. Generating heat too rapidly will thermal shock the rotors. Likewise, when bedding in a new set of brake pads it is best to perform the process on a used rotor. This new/used bedding process permits controlled bedding of each individual component.

Make sure rotor surfaces are free from oils, grease, and brake fluid. Run vehicle up to a moderate speed and make several medium deceleration stops to heat up the rotor slowly. This will help reduce the chance of thermal shock caused by uneven heating of the rotor. Pull into the pits and allow the rotor to cool to ambient air temperature. Care should be taken not to ride the brakes into the pits as this may hot spot the rotor causing premature wear to the surface or structural damage.

By West Hawk on November 17, 2020. Yes, I recommend this product. Speedway Motors is America's Oldest Speed Shop® and has been a trusted source for specialty rodding and racing products and friendly expert advice for more than 72 years.